Founded in 2006, HANSIN is a national-grade High-Tech enterprise specializing in R&D, manufacturing, and sales, focusing on medium-large China 1"Pressure (High barrier HB)Aluminized ton bag Factory and 1"Pressure (High barrier HB)Aluminized ton bag Company. We can produce flexible packaging bags with different applications and various barriers, products’ sizes range from 1L to 220L to 1500L, and include aseptic bags, bag-in-box, IBC liners, and FIBC liners, which are widely used for storage and transport with food and non-food.

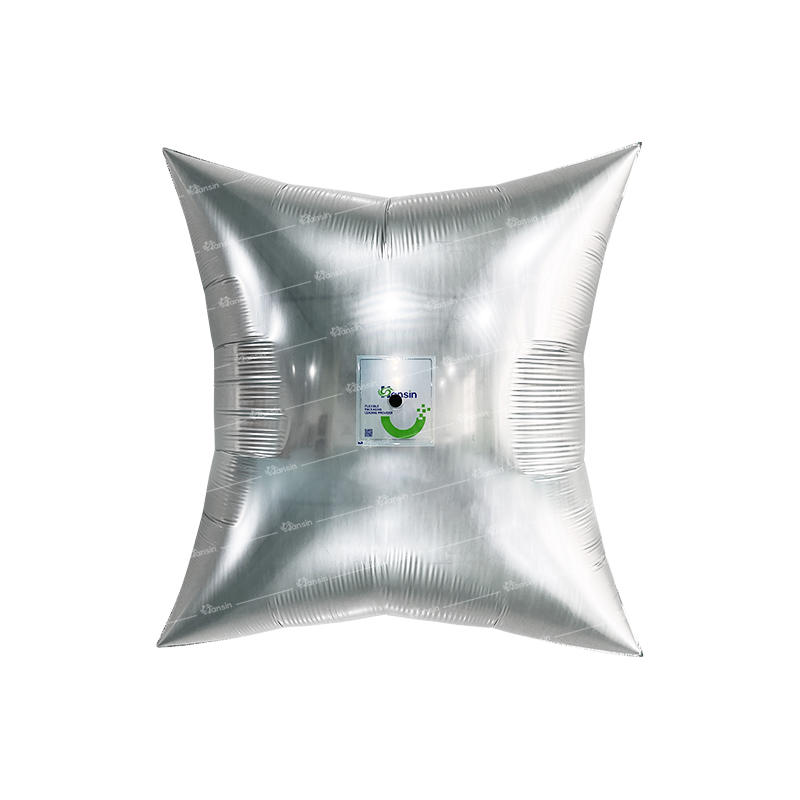

Hansin Aseptic Aluminum-coated Single spout IBC Liner: Optimized Liquid Handling Efficiency

Hansin's sterile aluminum-coated single-spout IBC liner provides an efficient and cost-effective solution for a variety of liquid handling needs. These liners feature a single-spout both for filling and discharging, optimizing container space, reducing operating costs and minimizing the risk of contamination. They are versatile across industries and are a sustainable choice for environmentally friendly fluid management. Hansin's IBC tank liners are available in sizes from 1000L to 1500L to meet a variety of manufacturing and supplier requirements.

Efficient and simple:

Hansin's single-spout IBC liners offer efficiency and simplicity in liquid handling. With strategically positioned filling and discharging , they optimize space utilization, reduce costs and minimize the risk of contamination.

Space optimization:

These liners utilize a single spout to maximize space within the container and potentially reduce storage and shipping costs while maintaining a streamlined design.

Cost-effective processing:

For companies looking for cost-effective liquid handling solutions, Hansin's liners offer a practical alternative that simplifies operations and reduces costs.

Reduce contamination risk:

The lining design minimizes the risk of contamination and ensures protection from external elements during filling and emptying, meeting strict quality standards.

Cross-industry versatility:

Hansin's single-spout IBC liners are compatible with a wide range of liquids, from chemicals to food and pharmaceuticals. They simplify inventory management and reduce the need for multiple liner types.

Environmental friendly:

These liners contribute to environmental sustainability by minimizing the need for complex liquid handling systems and waste and perfectly adapting to environmentally friendly practices.

中文简体

中文简体 英语

英语 西班牙语

西班牙语 俄语

俄语 葡萄牙语

葡萄牙语 法语

法语 德语

德语 意大利语

意大利语